动态停缸

DSF®技术使乘用车的效率提高5-15%。

动态停缸(DSF®)如何工作

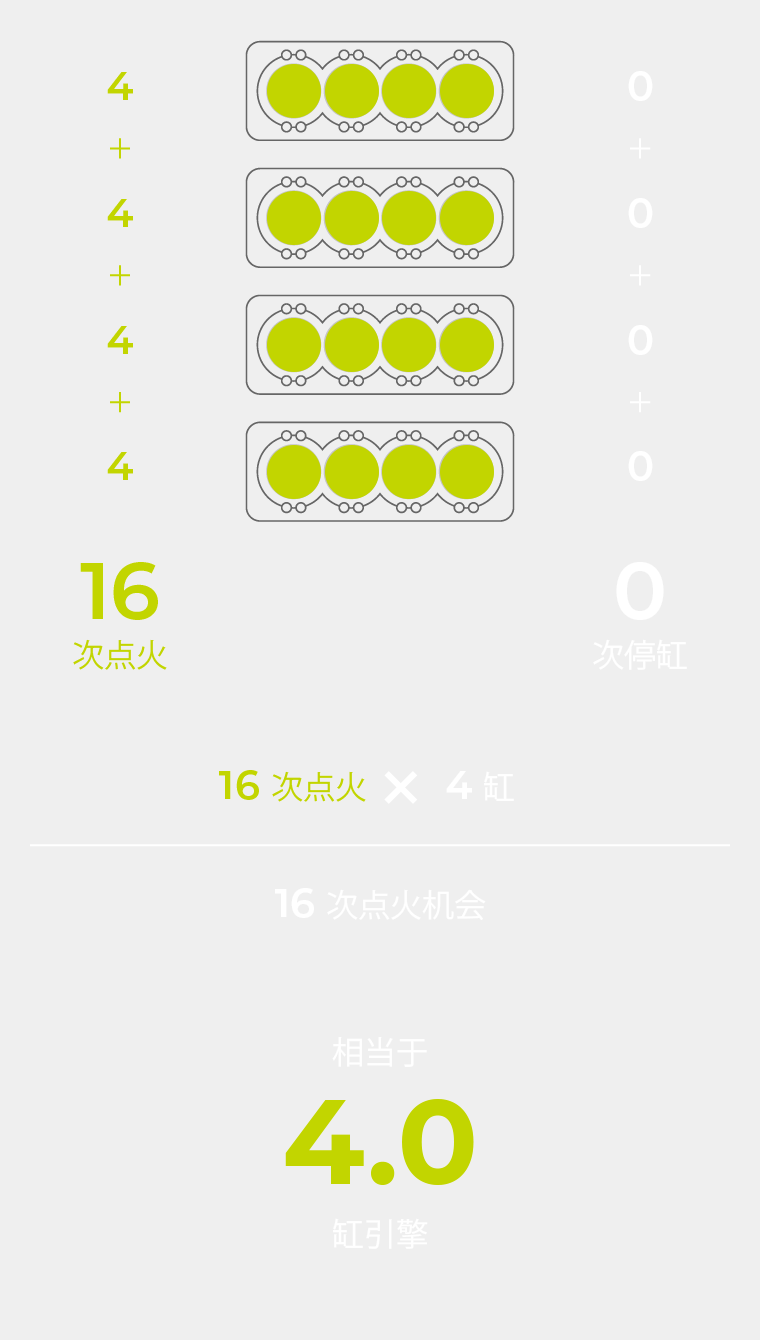

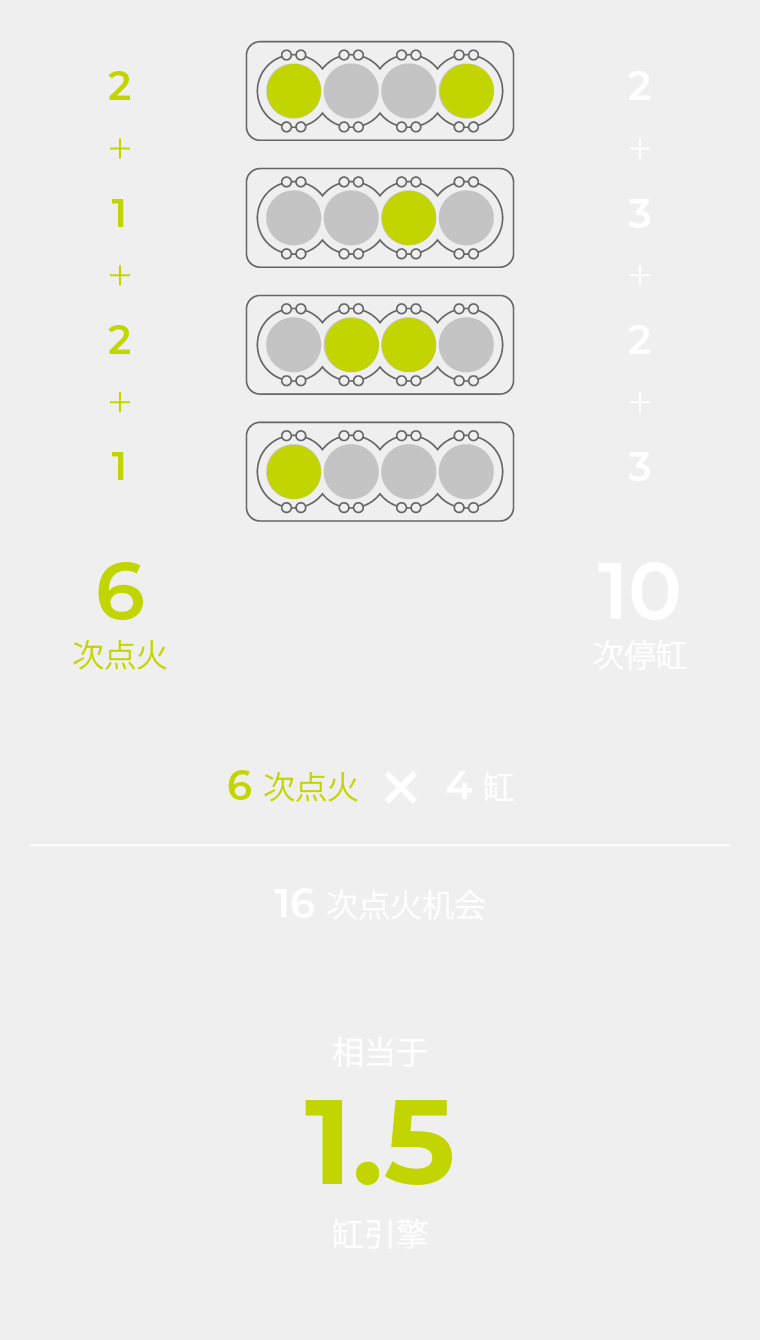

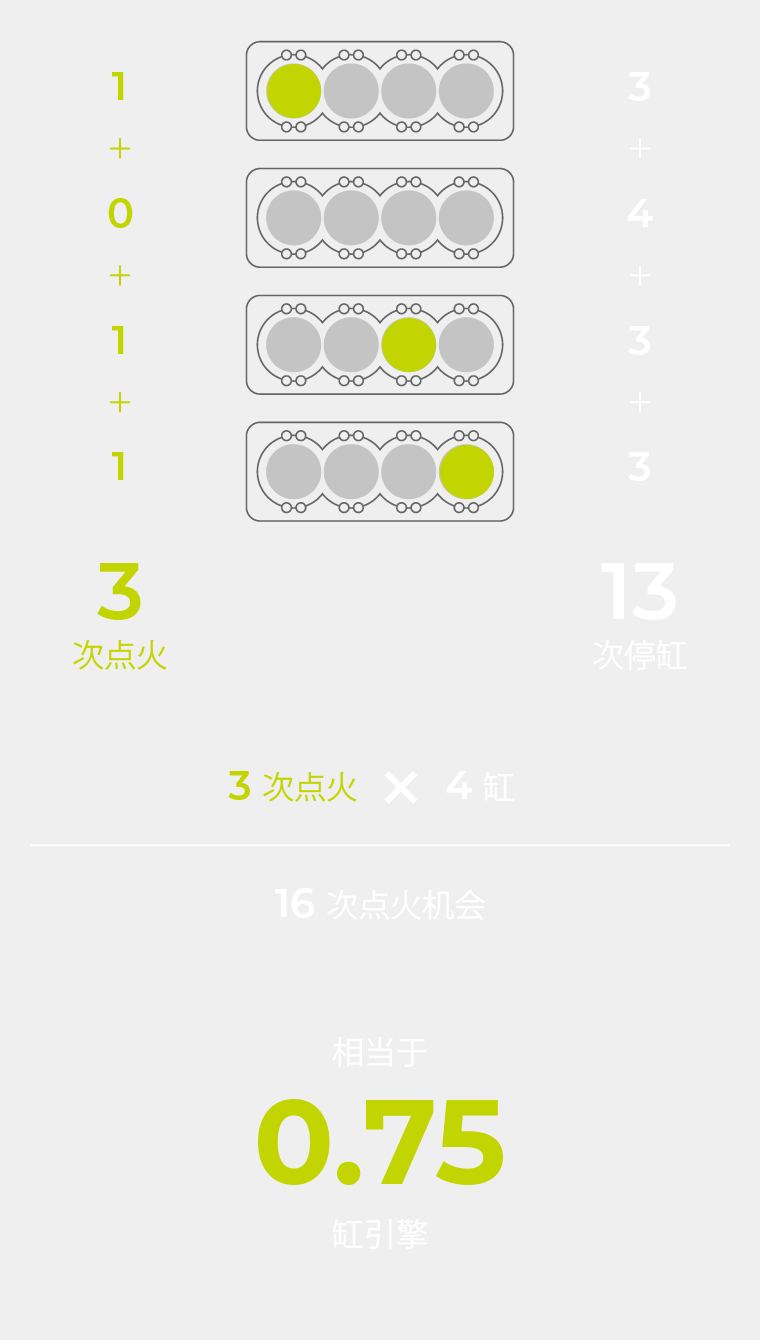

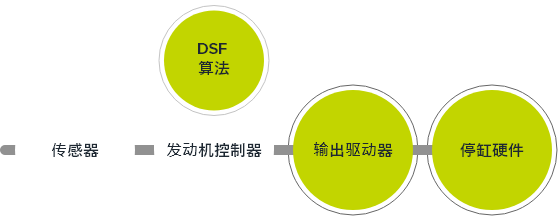

DSF ,在逐个事件的基础上动态地跳过或点燃单个气缸,以满足发动机扭矩的需求。通过使用专利算法仔细控制燃烧事件的数量和顺序,使发动机运行在接近峰值效率点,创造了一个由软件控制的可变排量发动机。图拉的算法避免了噪声和振动的产生,使驾驶员在所有驾驶条件下都能获得预期的精致度。

DSF®在现实世界的情况下

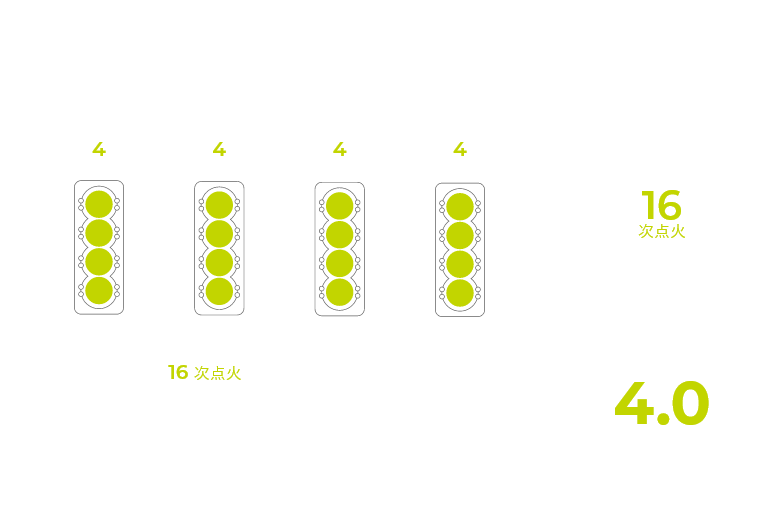

高扭矩

并入高速公路

当需要高扭矩时,DSF®激活所有气缸。

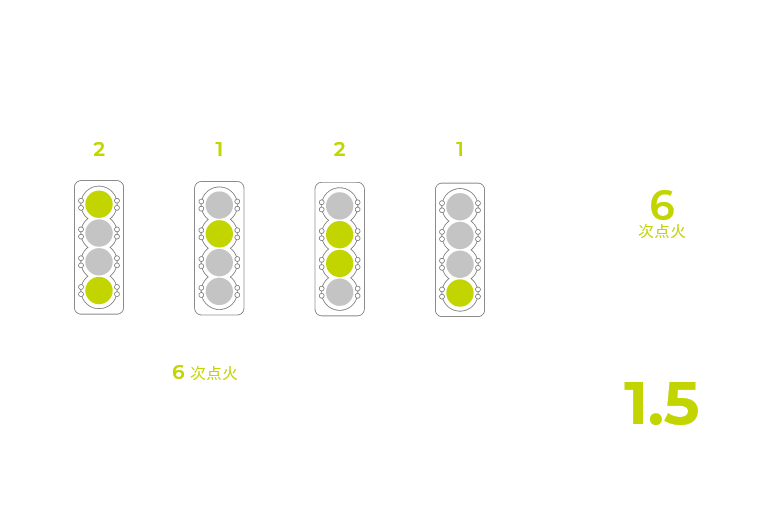

中等扭矩

高速公路巡航

随着扭矩需求的缓和,根据需求有些气缸会动态地停用。

低扭矩

低速巡航

在较慢的速度下,通过动态停用更多的气缸,甚至在减速时停用所有的气缸来保持最大的燃油效率。

如何实施DSF

发动机控制模块中的软件

DSF®可以用现有技术实施

停缸硬件

机油压力控制锁销位置

凸轮不激活气门

图拉公司的DSF ,可与大多数停缸气门驱动系统配合使用。

DSF 基于单个气缸的停用。每个气缸的点火或停用需要由能够单独启用/停用的进气门和排气门控制。

气门的停用可以通过液压或机电手段。

DSF 有一个很好的价值主张,今天有200多万辆车在路上,DSF ,就是证明。

比竞争对手的燃油经济性方案高出2倍以上的价值

适用于所有发动机类型

高达5-15%的燃油节省效益

每辆车每年最多可以减少1吨的二氧化碳排放

图拉开发了 达到燃油效率规定的基本技术之一

点击了解更多关于图拉, 及图拉对清洁地球的承诺

动态效率

从图拉开始