2022年6月

SIA国际会议和展览

的电动车使用永磁(PM)电机。

永磁电机是有问题的,因为稀土元素(REE)的供应短缺。这就是为什么该行业正在向无RE的电机发展。

动态电机驱动(DMD)消除了对稀土元素的依赖,让你用更低的成本获得更高的效率。

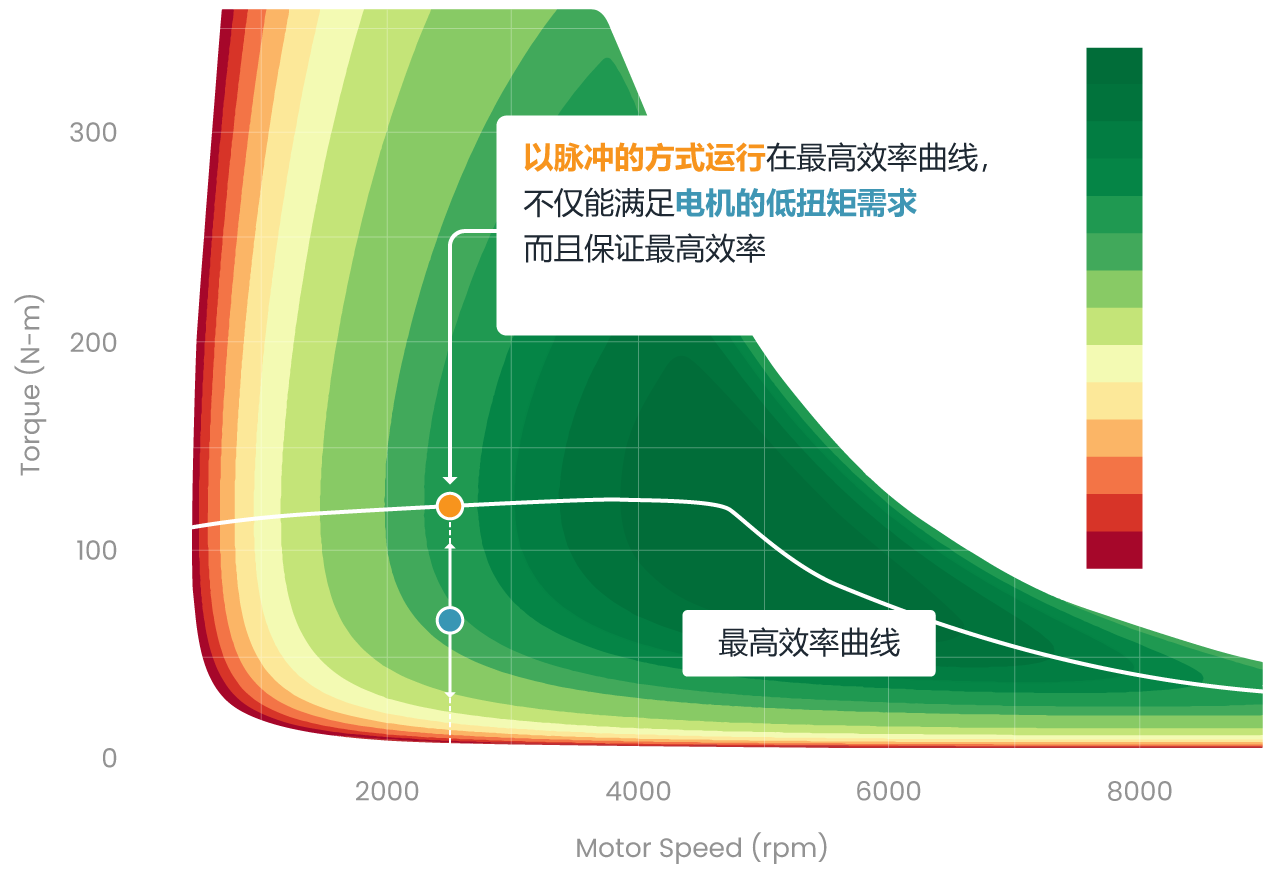

当扭矩要求较低时,DMD ,用磁场脉冲的方式运行在最高效率点。相比之下,运行在连续模式的传统电机无法提供如此高的效率。

伴随着电气化转型,对稀土磁铁的依赖、续航里程焦虑以及电池成本是迫在眉睫的问题。DMD 提出了一个基于软件且低成本的效率解决方案,不受稀土金属带来的环境和成本影响。

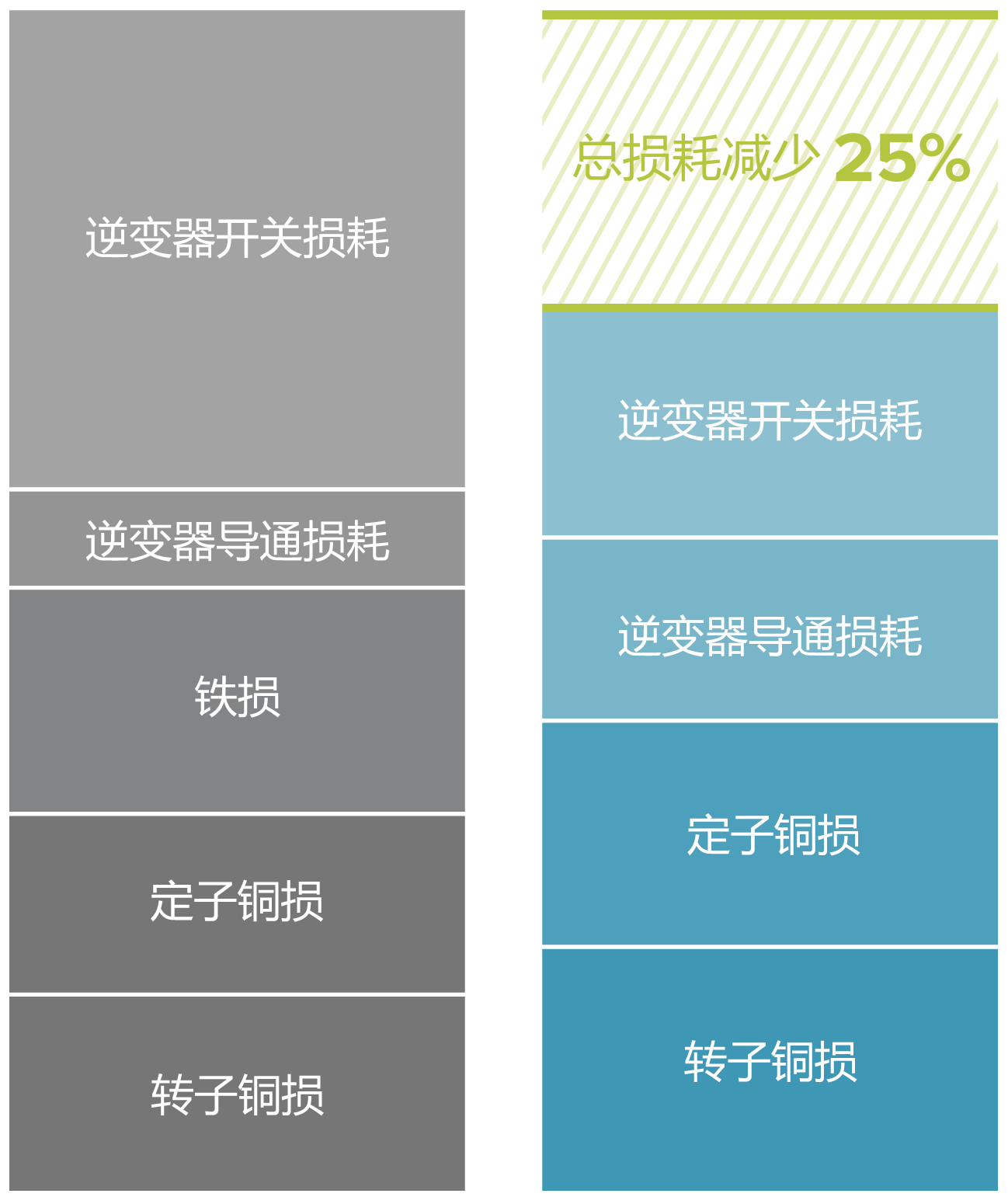

DMD 通过减少铁损和逆变器的开关损耗,使系统更加高效。结果呢? 减少25%的能量损失。

DMD 是一种软件解决方案,可以改善外激式同步电机(EESM)和其他无RE的电机。DMD 软件完善了现有系统,使EESM在低速时和高速时一样高效。现在你可以获得没有RE的效率。

电动车驱动电机的主力军,但依赖昂贵且有供应链问题的稀土元素

用铜取代稀土磁铁,既能获得与内置永磁同步机相同的高效率,又降低成本

不使用磁铁,主要用于辅助驱动

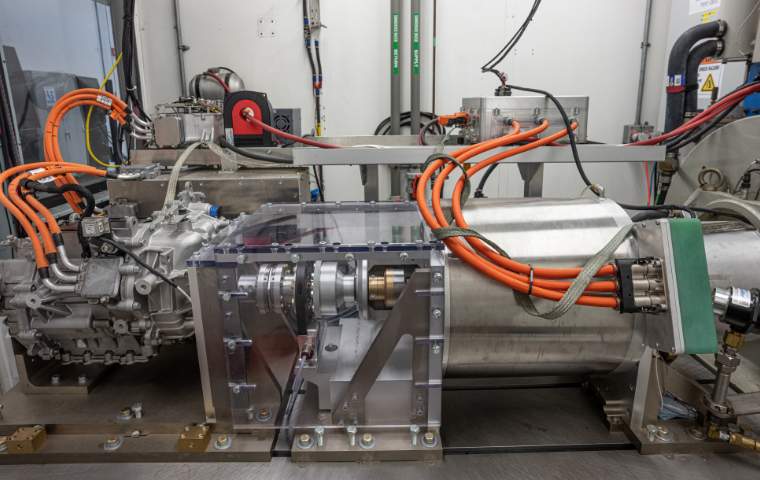

测功机工作已经证明了DMD 的价值;车辆展示了公路驾驶性能和客户的接受度。

图拉还向客户提供设计咨询、研发和知识产权许可服务。

我们用于车辆牵引电机研发的150kW测功机,正在实验室证明DMD所带来的效率提升。

DMD 还有助于工业界体验效率的大幅提升,不仅节能,而且加速向没有稀土材料的未来过渡。

不需要磁铁,在工业市场上占主导地位

用电力电子器件满足最新的IE5法规

低成本、坚固耐用,比感应电机效率更高